As we all know, when it comes to running a commercial kitchen, hygiene, rules and regulations are everything. All professional caterers have a legal (not to mention ethical) duty to uphold the standards set by the Food Standards Agency.

FSA ratings can make or break an establishment – with some areas requiring establishments to display their ratings where it is easy for customers to see them, whether online or on the front door.

With all eyes on hygiene – even more so in light of the current health crisis – having a well-oiled routine in place could be the secret to keeping your business clean, comfortable and commercially successful. And while we’re talking “C’s” – let’s quickly go over the four C’s of food hygiene: cooking, chilling, cross-contamination and cleaning.

While, of course, these are all areas you are already managing – it may be worth a recap on best practice to see if there are any areas that could be tightened up. Ask yourself:

- What type of surface is being cleaned?

- What is the nature of the soil being removed?

- What is the aim of the cleaning action?

- What kind of procedural cleaning activity is being implemented?

- Is the cleaning process well validated?

- Is the cleaning process adequately verified?

- How effective is the cleaning process?

- How efficient is the cleaning activity?

- Are the processes being supported by valid, scientific, technical and credible references?

- Are remedies in place to correct and prevent anything significant that could go wrong?

Source: https://www.food-safety.com/articles/1112-sanitation-and-cleaning-best-practices

So, what does best practice look like in a UK kitchen?

Colour code your cleaning equipment and areas

In the late 1990s, the British Institute of Cleaning Science developed a universal colour coding system for cleaning equipment which remains the standard in kitchens today:

Red: Washrooms and Toilets

Yellow: Kitchen and Food Prep areas

Blue: Restaurant and Bar

Green: Public Areas

This limits the spread of germs across areas – after all, you wouldn’t want to use a mop that has been used on the floor of your washrooms in your kitchen. You can apply the system to mops, brushes, sponges, cloths – any cleaning equipment you have in your establishment. While it’s important to be aware that the colour code may vary from business to business, as long as you assign separate colours to separate areas, you will dramatically reduce the risk of cross-contamination.

Create a cleaning regimen

The secret to a squeaky clean kitchen is routine. Work with staff to draw up a cleaning schedule where everyone knows exactly what their responsibilities are before, during and after their shift. One of the best and simplest ways to do this is by drawing up a cleaning checklist. This ensures consistency, fairness and accountability – and, of course, prevents cross-contamination, poor food hygiene and even infestation. From deep cleaning your commercial ovens to wiping out your fridge and flushing your espresso machine with hot water, every appliance in your kitchen will require specialist care – so it is important it gets a spot on your cleaning checklist.

Application range

Manufacturers of air and surface sanitiser/sanitiser units often tailor their products for specific environments such as hospitals or domestic spaces. As a food service outlet, you’re likely to need a versatile system that provides excellent results in multiple settings. For example, the HyGenikx range has been developed for use in cold rooms and food preparation areas, but it’s also perfect for washrooms or front of house.

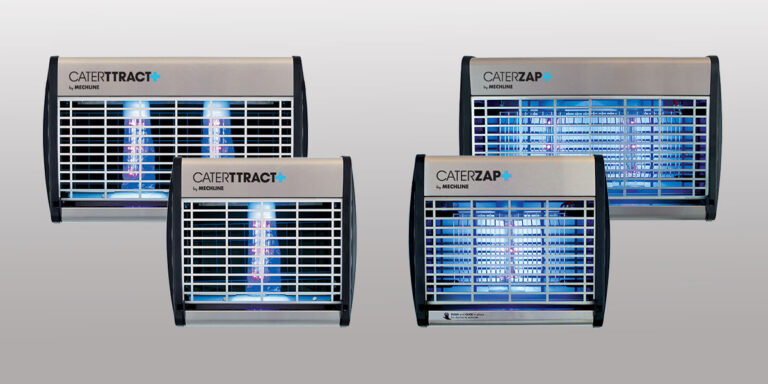

Use industrial sanitisers and sanitisers

Used alone, commercial disinfectants are not enough to prevent cross-contamination. Where best practice is concerned, we tend to view disinfectants as a temporary solution – after all, a single bacteria cell can multiply by up to one million times in an hour. Industrial air and surface sanitisers and sanitisers complement standard cleaning techniques, as they don’t just get rid of visible dirt and grime. They kill the microorganisms that spread infection and which can pose serious risks if left unchecked in the kitchen.

Clean high-frequency touchpoints and forgotten areas

It’s not all about the ovens and fridges. Some of the most common touchpoints in the catering business include toilet flushes, light switches, taps, hand dryer buttons and soap or towel dispensers. Don’t forget:

- High shelves

- Drains and gullies

- Awkward spaces in between walls and equipment

- Underneath appliances: cookers/fridges/freezers and other surfaces

- Seals and fridge doors/shelves

- Filters and plenum chambers

- Ventilation systems

- Dishwashers

Source: https://www.nisbets.co.uk/ultimatekitchencleaningguide

Then, there’s the most often-forgotten area of all – your walls. Left alone, kitchen walls can quickly accumulate muck, grease, condensation and other nasties – making them a veritable theme park for bacteria. While it doesn’t make sense to scrub your walls mid-shift, we advise cleaning your walls each day after closing to ensure you’re removing dirt, rather than simply moving it around.

Provide excellent handwashing facilities

All of your cleaning efforts will be for nothing if your employees are walking around with germs on their hands. During prep, foods and surfaces can quickly become contaminated. Provide hand washing posters and rigorous training, and make sure you have separate sinks and basins for dishwashing and hand washing. Hands-free basins are a particularly worthwhile investment, helping reduce touchpoints and, you guessed it, prevent cross-contamination.

Having these practices in place will give you, your staff, and your customers complete confidence in the standards of your establishment. After such a shock to the system, advertising just how hard you are working to make your restaurant safe will give customers more faith in your premises and (hopefully) get them back through the door – albeit with higher expectations.

To explore other measures you can put in place to increase customer confidence, download our handy guide, “6 Steps to Increasing Restaurant Covers and Footfall”.