Hygiene and safety have always been cornerstones of the food service industry. Now, in light of the coronavirus pandemic, the need for confidence in our health and safety measures has never been greater. From proper handwashing to being more conscious of those we share public spaces with, we all have a role to play in keeping each other safe. For those of us working in kitchens, that means looking after our colleagues and customers by upholding best-in-class standards in infection control and food safety.

While it goes without saying that implementing additional hygiene measures is a priority right now, this can be enormous pressure for operators – especially when layered on top of restrictions on the hospitality and leisure space and all the other concerns dominating the sector right now.

Kitchen staff have strict cleaning schedules to adhere to, with many relying on the use of commercial disinfectants to prevent cross-contamination. Sticking to this kind of routine is incredibly important – but what if the products being used aren’t as effective as you might think?

As an operator, it’s important to know that standard room cleaning and disinfecting procedures only offer a temporary solution when it comes to avoiding cross-contamination and infection in the kitchen. Here we explain where and why such products are falling short – and explore how introducing air and surface sanitisers/sanitisers can complement your cleaning techniques.

Cross-contamination in the hospitality industry

There are three main types of cross-contamination lurking behind the scenes in hospitality. First, food-to-food, where the adding of contaminated foods to non-contaminated foods can allow bacteria to spread quickly. Raw, undercooked, or improperly washed food can harbour large amounts of bacteria, such as salmonella and E. coli – and we’re not just talking about meat and seafood. Some of the biggest offenders also tend to be leafy greens, beansprouts, leftover rice, unpasteurised milk, soft cheeses, deli products – and, of course, raw eggs. Leftovers kept in the fridge too long can also result in a sudden burst of bacteria.

Secondly, bacteria like these can also spread from equipment to food and can survive for long periods on surfaces, utensils, cutting boards, storage containers, and food manufacturing equipment.

Finally, and perhaps most worryingly, we have people-to-food contamination, where bacteria can be easily transferred via people’s hands, bodies, or clothing. This is likely to be something very much on people’s minds this year.

So, how can you prevent cross-contamination? Staying vigilant means more education around food safety, thorough cleaning of utensils and workspaces, and, of course, plenty of hand soap! There is a reason 2020 will go down in history as The Year of Handwashing. By far the most effective way to reduce the risk of cross-contamination is to wash your hands with soap and water for at least 20 seconds. Keeping your kitchen and site clean is the single best thing you can do to avoid cross-contamination – but it’s important to know that even the best commercial disinfectants aren’t always enough.

Why commercial disinfectants alone are not enough to prevent cross-contamination

If you were to search a catering wholesale site for commercial disinfectants, you’d usually find that they are categorised along with sanitisers. While disinfectants are a crucial part of the cleaning process, they cannot be used alone. Why? There are three main reasons.

First, we tend to forget that disinfectants are a temporary solution. Just because your surfaces are safe now, doesn’t mean that they will be safe in an hour. Microorganisms spread infections, compromise hygiene standards, cause food to spoil, create offensive odours, and can multiply quickly – all at an alarming rate! In just eight hours, a single bacterial cell can multiply to over 8 million. It’s no surprise that we find it hard to keep it at bay with traditional cleaning methods. Many business owners use heavily-fragranced products which, while smelling nice, merely mask odours rather than neutralising the odours themselves.

Industrial disinfectants and sanitisers are key in the fight against bacteria. Detergents clean surfaces and remove grease, but they do not kill bacteria and viruses. Sanitisers reduce and kill specific strains of bacteria to safe levels and can be used to both clean and disinfect as part of a two-stage process; first to remove any dirt, food and grease, and again to disinfect a visibly clean surface. Disinfectants provide a more powerful hit – again, against certain types of bacteria, and should be used on a visibly clean surface. Even then, it is important to get the timings right – leaving the product on the surface for precisely the amount of time stated in the instructions.

Lastly, as with many solutions, there is always room for human error when it comes to disinfectant. There may be areas that get missed, products wiped off too quickly, inaccurate dilution, or any of a whole host of other problems. Under-dilution where the person uses too much product and not enough water not only has financial implications, but could also damage surfaces and even compromise the safety of the person using the product. On the flip side, using too little product, or over-diluting it, could render your cleaning process useless, exposing your visitors to dirt and germs and heightening the risk of cross-contamination.

A long-term solution to support current cleaning techniques

There to support current cleaning techniques, surface sanitisers/sanitisation systems complement standard best practice, combatting airborne viruses, minimising their spread and making the risk of cross-contamination as small as possible. This helps in reducing the risk of infection, expanding the freshness of perishable produce and creating a healthier and cleaner work environment.

By introducing air and surface sanitisers/sanitisers into your premises you can amplify the effectiveness of your normal cleaning schedule and achieve significantly higher hygiene standards on hard-to-reach surfaces in your commercial food prep areas.

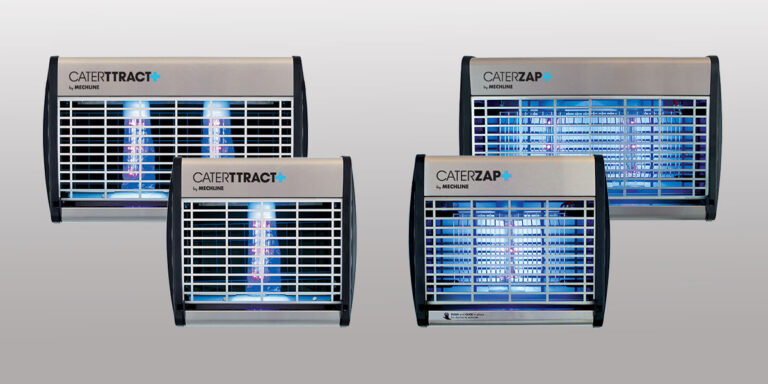

The Mechline HyGenikx range utilises a combination of the most effective air and surface sterilisation technologies available. The wall-mounted systems go quietly to work in the background, attacking harmful bacteria, fungi, volatile organic compounds, moulds, and viruses to provide around the clock protection. Learn more about the HyGenikx range.

To learn more about how to improve the efficiency on your restaurant click below.