In 2018, a restaurant in Shrewsbury was ordered to pay £9,000 to the local water board after it was discovered that fat from its kitchen was gathering in the drains and had blocked a local sewer. Unfortunately, this establishment had a poor defence since it had failed to comply with requests for the installation of a grease management system and did not indicate that it would be doing this in the future.

Failing to install proper equipment and allowing fats, oils, grease and starches (FOGS) to build up and enter the water system isn’t just negligent and an inconvenience to the local community; it’s also an offence, with the potential to cost your business thousands of pounds in fines and lost sales during closure – not to mention all the bad PR for your business. The good news? It is also completely avoidable.

What does the Water Industry Act say?

In order to act responsibly, it’s important that you first understand the law and what is required of you and your business.

The Water Industry Act 1991

Under section 111 of the Water Industry Act 1991, it is a criminal offence to release anything into the public sewers that could interfere with the free flow of wastewater. When unsuitable objects and substances make their way into the sewers, there is a very real and serious threat of damage to the environment, not to mention local homes and businesses. If a water company is able to link a blockage to your business, they will not hesitate to prosecute the individuals responsible. This could mean an unlimited fine – or even imprisonment.

When it comes to understanding the law, it is important that you are crystal clear on the regulations that apply to you and your business. We recommend that you take the time to read through the regulations relating to your business and the five most important things you need to know in order to stay on the right side of the law.

How can your restaurant avoid a water company fine?

When it comes to keeping your kitchen in line with regulations, it is far better to act preventatively and be proactive in your solutions, rather than risking non-compliance and the potential consequences that come with it.

Here we outline what best practice FOGS management looks like:

The Do’s and Don’ts

Do:

- Scrape leftovers from plates, pans and utensils before placing them in the sink to wash.

- Use a sink strainer.

- Install a FOGS management system. Keep this clean and well maintained.

- Collect frying oil and leftover fat in airtight containers to be collected by a licensed waste contractor.

Don’t:

- Allow leftovers to enter your sink.

- Don’t sweep debris and leftovers into your drains.

- Do not pour any FOGS down your drains.

- Don’t dissolve blockages with bleach or hot water, as this method is ineffective.

What equipment can help you manage restaurant grease?

There are a variety of solutions out there to help you manage your FOGS – but it’s not always a case of choosing the most obvious or most cost-effective solution. Each of the following will have its own particular use case; it’s crucial that you choose the solution that best fits your business, building and region.

Work with a professional to acquire an intelligent appraisal of your premises and decide which FOGS management solutions will work best. This assessment should include kitchen design, equipment used, menu type, staff training, and working procedures, in order to develop an effective system that minimises the risk of FOGS entering the drainage system.

Possible solutions include:

Grease traps

Grease traps have been around since the Victorian days and are a simple yet largely effective way of catching grease before it leaves your premises and enters the sewerage system. They work on the well-established premise that oil and water don’t mix; therefore, as the grease rises within the container, wastewater flows out. Made from stainless steel, plastics or concrete, they are essentially a box that collects grease in wastewater. It’s imperative that they are only used for this purpose – grease traps should NEVER have wastewater from bathrooms etc., flowing through them. You’ll have to schedule a licensed waste collector to come and remove the accumulated grease on a regular basis.

Automated grease removal units (GRUs)

Automatic grease removal units are similar to grease traps, only a little more complex. As with a grease trap, GRUs are designed to remove free-floating oils and grease from wastewater, to ensure only water is able to journey on into the wastewater system. The big difference is that fat, oil and grease (FOG) are automatically removed from the main tank and put into a separate container—which can be easily emptied and stored, ready for collection. They require careful and regular maintenance and will usually alert you when they need attention, e.g. when it is time to empty them. Your container will get filled with grease pretty quickly, so it’s important to bear this in mind when scheduling your team’s daily routine. As with all grease management, it needs to be maintained, in order to function at its optimum, and to avoid odours and other unpleasant things from festering around your kitchen.

Accredited biological dosing systems

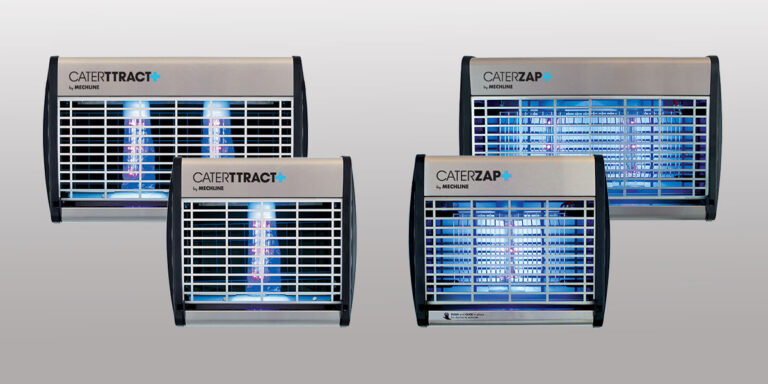

Designed to address the drainage problems found in commercial kitchens, biological dosing systems work by ‘dosing’ the drain with specially selected microorganisms that attach themselves to FOGS molecules and degrade them. These systems can be used alone or in combination with a grease trap. It’s important to note that not all biological dosing systems are the same, however. Mechline’s GreasePak, for example, uses a blend of specially selected microorganisms that are super efficient at degrading fats, oils, grease and starches, as well as being non-hazardous and environmentally friendly. If these factors are a concern to you, it’s important to check that the solution you choose is not only effective but also safe and not harmful to our planet.

It pays to think ahead when it comes to FOGS removal in your kitchen. Beyond the fine, your restaurant may also pick up the tab for repairs to the local sewer network. It’s worth noting that blocked drains also create a haven for pests such as flies and rodents. In order to avoid any of these potential headaches somewhere down the line, it is important to ensure you have the correct equipment and carry out regular training with staff to make sure everyone is kept up to date on best practice.